Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

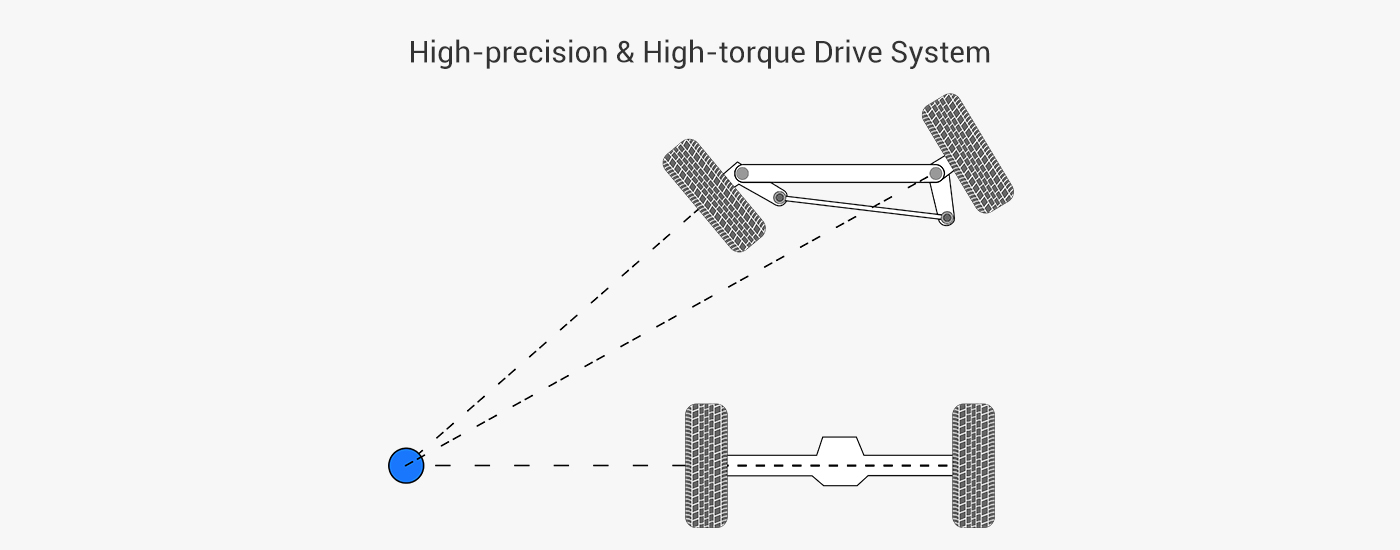

The outdoor 2wd robot platform is a modular platform specifically designed for high-performance mobile applications. Its core configuration features Ackermann steering paired with rear-wheel drive: the Ackermann steering system ensures precise trajectory control and minimal tire wear during high-speed turns, while rear-wheel drive delivers robust traction and load adaptability, enabling reliable mobility in dynamic environments.

The outdoor 2wd robot platform is a modular platform specifically designed for high-performance mobile applications. Its core configuration features Ackermann steering paired with rear-wheel drive: the Ackermann steering system ensures precise trajectory control and minimal tire wear during high-speed turns, while rear-wheel drive delivers robust traction and load adaptability, enabling reliable mobility in dynamic environments.

Table Parameters

| Design Dimensions | 1880mm*1025mm*585mm | Gross Vehicle Weight | 300kg |

| Structural Configuration | Front-wheel steering, rear-wheel drive | Suspension Type | Solid axle suspension |

| Ground Clearance | 125mm | Wheelbase | 1050mm |

| Wheelbase | 825mm | Tire Diameter | 508mm |

| Minimum Turning Radius | 2.6m | Battery | 72V/81AH |

| Charging Time | ≤4.5h | Charging Method | 72V/20A charger manual charging |

| External Power Supply | 72V/20A 24V/15A 12V/15A | Braking System | Hydraulic disc brakes + motor braking |

| Parking Method | Motor parking brake + Hydraulic disc parking brake + Electromagnetic holding brake | Vertical Load Capacity (Level Surface) | 600kg |

| Operating Speed | 14km/h | Fording Depth | 125mm |

| Range | 95km (unloaded)/75km (fully loaded) (81Ah) | Maximum Gradeability | 30° fully loaded/10° unloaded |

| Crossing Width | Unloaded/Fully loaded 300mm | Obstacle Clearance | 140mm (unloaded)/100mm (fully loaded) |

| Protection Rating | IP44 | Communication Method | CAN2.0B |

| Operating Temperature | / | Optional Equipment | APOLLO Open-Source Navigation Kit/Autoware Open-Source Navigation Kit/NV-auto Commercial Navigation Kit/Combined Inertial Navigation RTK/Automatic Charging Station/Robotic Arm/LiDAR/Depth Camera |

By delivering high-speed, stable handling, seamless adaptation across diverse scenarios, and minimal operational costs, we address the pain points of efficiency loss and operational disruptions caused by unstable chassis, poor adaptability, and frequent maintenance in complex environments.

What is Ackermann steering?

It ensures all wheels roll around the same instantaneous center of steering (ICC) during turns, preventing tire skidding (reducing tire wear, improving control precision, and saving energy).

Implementation Method:

The inner front wheel (steering wheel) has a greater steering angle than the outer front wheel.

The steering angle difference between the two front wheels is precisely controlled via a steering trapezoidal linkage mechanism (or electronic control in modern robots).

The rear wheels are typically fixed drive wheels (or differential drive) and do not participate in steering.

Why do robots use Ackermann steering?

Zero-slip turning: Ideal for soft outdoor surfaces (grass, sand, mud) to prevent positioning drift caused by sideways slippage in differential-drive robots.

High path-tracking accuracy: Suitable for scenarios requiring fixed-path operation, such as farmland inspections, logistics transportation, and surveying.

Low energy consumption and wear: Pure tire rolling reduces friction, extending endurance and tire lifespan (compared to Mecanum wheels/omnidirectional wheels).

High-speed stability: More stable than differential steering at high speeds (>2m/s), minimizing tail-out (e.g., security patrol robots).

Eight-Layer Security Protection System: This comprehensive defense features dual hardware and software safeguards that operate simultaneously without conflict. Even under the harshest conditions—heavy rain, dust, high temperatures, or electromagnetic interference—it provides you and your field personnel with a true last line of defense.

Communications BCC Protection | Even in environments with extremely strong electromagnetic interference, such as ports, steel mills, and mining areas, critical commands like forward movement, steering, and braking are guaranteed to remain 100% tamper-proof. |

Overtemperature Protection | The motor, driver, battery, and key chips on the power board all incorporate independent NTC temperature sensors for real-time temperature monitoring. |

Short Circuit Protection | Whether it's wiring harness insulation failure causing short circuits in rainy weather, salt spray corrosion at ports leading to connector breakdown, or forklift collisions severing cables—power is cut off before sparks appear, completely eliminating the possibility of “chassis smoke and fire.” |

Emergency Stop Protection | Both the robot body and remote controller feature a red emergency stop mushroom-head button. Pressing it once physically hard-disconnects the main contactor, completely cutting power to the vehicle's battery within 0.1 seconds. All motors lock up and lose power, achieving a braking distance of ≤30cm. This ensures that in any hazardous situation, the robot can be brought to a complete stop instantly. |

Overload Protection | The outdoor 2wd robot platform continuously monitors the current of each motor phase and the total input current. When the load exceeds 120% of the rated capacity for over 5 seconds, the system automatically reduces speed and limits power output. If the load exceeds 150%, an alarm is triggered immediately, and the system gradually stops to prevent prolonged overload conditions that could cause motor stalling, driver board failure, or battery over-discharge. |

Steering Limit Protection | The steering motor incorporates a high-precision absolute encoder + dual mechanical hard stops. |

Communication Heartbeat Protection | If the robot fails to detect the remote controller's signal for three consecutive times (indicating communication failure or disconnection), it immediately enters “Safety Mode”: - Automatically level the ground - Decelerate in place - Stop completely - Engage the brake lock This completely eliminates the risk of runaway accidents. |

Communication Timeout Protection | Each key command (such as move forward, turn, or raise/lower) has a maximum response time limit (default 1 second). |

1. Outdoor Inspection Robots: In scenarios such as power line inspections, photovoltaic power plant maintenance, and orchard monitoring, robots must operate stably over extended periods on unstructured terrain (e.g., muddy ground, gravel roads, inclined ramps). Ackermann steering significantly reduces the risk of tire sinking in soft ground through its zero-side-slip turning capability.

2. Logistics AGVs: Large-scale outdoor warehouse transfer scenarios demand AGVs with both high load capacity (1-10 tons) and precise docking accuracy (error <±5mm). The outdoor 2wd robot platform efficiently converts power into traction through its rigid frame and independently driven rear wheels.

3. Research & Education Platforms: Universities and research institutions widely adopt Ackermann chassis as teaching vehicles for autonomous driving education.

4. Special-Purpose Robots: High-risk scenarios like fire reconnaissance and nuclear power plant inspections impose stringent demands on robots' extreme environment adaptability. Crawler structures easily get stuck in debris, while omnidirectional wheels slip on rubble surfaces. The outdoor 2wd robot platform, featuring large-diameter off-road tires and pure rolling steering, maintains trajectory precision even on 30° rubble slopes.

5. Low-Speed Autonomous Vehicles: Level 4 autonomous vehicles for campus delivery and scenic area navigation operate in mixed pedestrian-vehicle environments.

Related Accessories

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +