Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

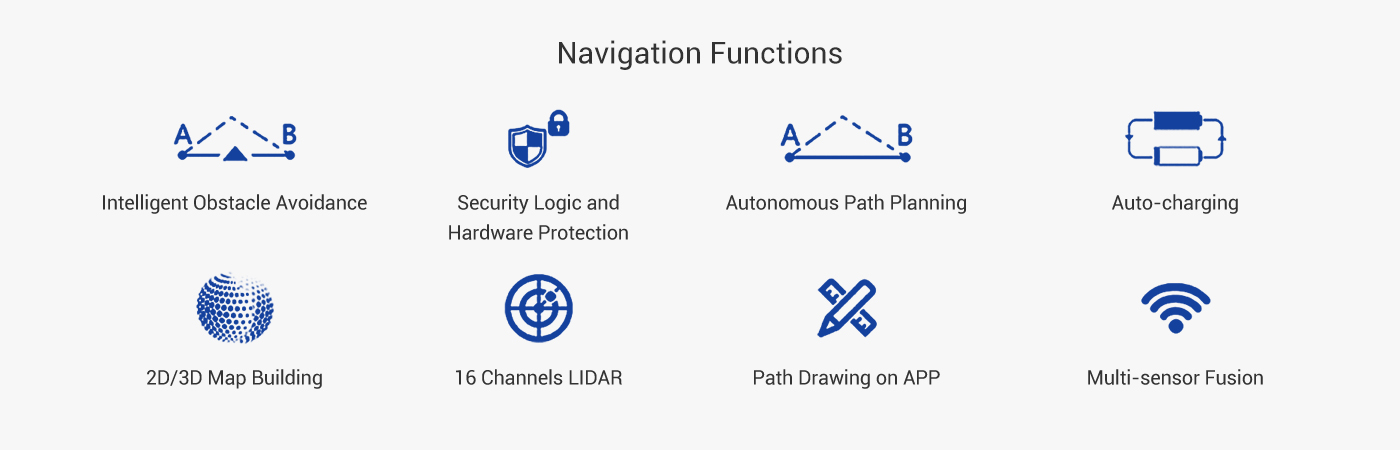

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

A rear-wheel drive smart robot chassis is a mobile robot platform where the rear wheels provide propulsion, while the front wheels achieve coordinated steering through an Ackermann geometry mechanism (such as linkages or independent motors). This ensures that all wheels roll around the same instantaneous center during turns, preventing tire side slip. It enhances positioning accuracy (due to the absence of sliding errors, odometer data is more reliable) and stability during high-speed straight-line driving, while reducing tire wear and energy consumption. It is particularly suitable for precise path tracking in long-distance, open environments.

This rear-wheel drive chassis is primarily suited for outdoor scenarios with ample space, such as farmland monitoring, park patrols, autonomous driving research platforms, or flat outdoor areas in large logistics warehouses, where low zero-turn radius requirements are combined with the need for reliable positioning.

A rear-wheel drive smart robot chassis is a mobile robot platform where the rear wheels provide propulsion, while the front wheels achieve coordinated steering through an Ackermann geometry mechanism (such as linkages or independent motors). This ensures that all wheels roll around the same instantaneous center during turns, preventing tire side slip. It enhances positioning accuracy (due to the absence of sliding errors, odometer data is more reliable) and stability during high-speed straight-line driving, while reducing tire wear and energy consumption. It is particularly suitable for precise path tracking in long-distance, open environments.

This rear-wheel drive chassis is primarily suited for outdoor scenarios with ample space, such as farmland monitoring, park patrols, autonomous driving research platforms, or flat outdoor areas in large logistics warehouses, where low zero-turn radius requirements are combined with the need for reliable positioning.

Parameter Table

| Type | Medium rear-wheel drive robot platform | |

| ● Standard configuration ○ Optional configuration - Not available | ||

| Chassis Specifications | Energy type | Pure electric (lithium iron phosphate battery) |

| Length*Width*Height(mm) | 3550*1300*650 | |

| Minimum ground clearance(mm) | 155 | |

| Minimum turning radius(m) | 4.2 | |

| Maximum fording depth(mm) | 195 | |

| Maximum obstacle clearance height(mm) | 120 | |

| Maximum climbing angle(%) | 20 | |

| Maximum speed(km/h) | 40 | |

| Curb weight(kg) | 620 | |

| Maximum payload(kg) | 1080 | |

| Battery and Charging | Battery capacity (kWh) | 18.4 |

| Range on empty (km) | 150 | |

| Slow charging time (hours) | 4 hours | |

| Wireless Drive Parameters | Drive type | Rear-wheel drive |

| Motor rated/peak power (kW) | 7.5/15 | |

| Motor rated/peak torque (Nm) | 24/90 | |

| Smart Hardware Features | OTA remote updates | ● |

| Backend data monitoring system | ● | |

| Remote start/stop | ● | |

| Tire pressure monitoring | ● | |

| Four-wheel speed detection | ● | |

| Hill start assist/hill descent control | ● | |

| Low speed alert | ● | |

| Emergency stop button | - | |

| Independent front/rear touch bar emergency stop | ● | |

| Remote control | ● | |

High Positioning Accuracy

The core advantage of the rear-wheel drive chassis equipped with Ackermann steering lies in its significantly improved positioning accuracy. The Ackermann steering mechanism uses geometric design (such as trapezoidal linkages or independent motor control) to ensure that all wheels roll purely around the same instantaneous center when turning, completely avoiding lateral tire slippage.

In long-distance navigation tasks (such as farmland boundary mapping or park patrols), this chassis provides centimeter-level path tracking accuracy, significantly reducing reliance on additional sensors (such as lidar or vision systems), thereby simplifying the computational burden of SLAM (Simultaneous Localization and Mapping) algorithms. It is suitable for outdoor environments with stringent requirements for positioning robustness.

High-Speed Stability

Rear-wheel drive provides powerful traction, especially when accelerating or climbing slopes, effectively distributing the center of gravity (heavy objects such as batteries are placed at the rear) to prevent front wheel slippage. Ackermann steering coordinates the steering angles of the front wheels (the inner wheel has a greater steering angle than the outer wheel) to ensure smooth turns without the risk of skidding.

It reduces yaw and body sway during high-speed driving, enabling the robot to operate stably in open areas such as logistics yards and campus roads.

Low Wear and High Energy Efficiency

The pure rolling characteristics of Ackermann steering significantly reduce mechanical wear and energy consumption. Since there is no lateral slippage of the tires during turns, friction and wear between the rubber and the ground are avoided, extending tire life (especially on hard surfaces such as concrete or asphalt) while reducing additional energy consumption caused by sliding resistance in the drive motor.

The rear-wheel drive structure optimizes power transmission efficiency—the driving force is concentrated on the rear wheels, eliminating the need to distribute power to the steering wheels, allowing energy to focus on propulsion rather than overcoming steering resistance. This is particularly evident in long-distance tasks (such as 24-hour campus patrols or agricultural monitoring), reducing maintenance frequency and battery consumption, and improving overall endurance, making it especially suitable for energy-constrained or long-term outdoor deployment applications.

Long-Distance Path Tracking

The geometric consistency of Ackermann steering ensures that the robot chassis follows a highly predictable trajectory when traveling in a straight line or along a large-radius curve. Combined with the stable propulsive force of rear-wheel drive, it can reliably reproduce pre-set routes (such as straight furrows in farmland or fixed paths in logistics channels). Although its minimum turning radius is larger than that of differential drive, in spacious environments (such as open outdoor areas or the external zones of large warehouses), it avoids positioning jitter caused by sharp turns, enabling the robot to complete long-distance tasks at a constant speed efficiently. This makes it highly suitable for applications such as outdoor precision agriculture and infrastructure inspections.

Rear-wheel drive robot chassis + Ackermann steering design, suitable for environments where there are no excessive requirements for minimum turning radius, the ground is hard and flat, and tasks mainly involve long-distance straight-line or large-radius curve driving, and there are no mandatory requirements for zero turning radius.

Farmland Monitoring and Precision Agriculture Scenarios

The smart robot chassis is suitable for open fields where minimum turning radius requirements must be met for turning around. It completely eliminates tire slippage, ensuring positioning accuracy with cumulative error below 1% in straight furrows. This ensures precise alignment of fertilization or monitoring equipment with crop coordinates. The rear-wheel drive design provides stable hill-climbing capability, overcoming the muddy challenges of 15° gentle slopes in farmland.

Large-scale park patrol and security scenarios

The rear-wheel drive robot chassis is suitable for paved main roads in campuses, parks, or industrial parks. When the robot is cruising at high speed on asphalt roads, the powerful torque of the rear-wheel drive can meet acceleration requirements. Through precise coordination of turning posture, the yaw angle fluctuation of the vehicle body is suppressed to within 2°, and the path accuracy is stabilized at ±5 cm.

It is highly suitable for open environments, where paved surfaces maximize its non-slip characteristics, resulting in tire wear depth of less than 1 millimeter after 1,000 kilometers of operation.

Logistics Warehouse Outdoor Area and Autonomous Driving Test Site

The standardized lanes in the loading and unloading area of the logistics park provide precise maneuvering space for the chassis. On concrete roads, the robot chassis can transport goods at high speeds. The torque of the rear-wheel drive not only ensures stable acceleration when fully loaded, but also greatly reduces the risk of goods tipping over.

Infrastructure Inspection and Wide-Area Monitoring Scenarios

Along railway lines (gravel surfaces) or pipeline corridors extending for several kilometers, this smart robot chassis can perform uniform inspections of oil and gas pipelines. The Ackermann steering ensures that the odometer's cumulative error is less than 0.5%, guaranteeing that infrared sensor data is strictly aligned with geographic coordinates.

Rear-wheel drive enables the robot to easily navigate railway embankments with a 15° slope. Even at tunnel entrances where GPS signals are blocked, dead reckoning using the IMU maintains centimeter-level accuracy.

Related Accessories

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +