Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

The four-wheel drive robot chassis is a mobile platform that uses four independently driven and steered wheels. It achieves omnidirectional movement and on-the-spot turning through four independent motors and steering mechanisms. It is mainly used on paved roads and some light off-road scenarios, and can handle complex terrains such as slopes, gravel roads, and muddy ground. It is especially suitable for scenarios that require high-precision navigation and obstacle avoidance.

Four-wheel drive: Refers to a 4wd smart robot chassis where all four wheels are equipped with independent drive motors. Each wheel can be independently controlled for speed and steering (forward or reverse), providing powerful traction and precise speed control.

Four-wheel steering: This refers to a chassis where all four wheels have independent steering mechanisms (typically steering wheels or hub motors). Each wheel can independently and at a large angle (typically continuous rotation from 0° to 360°) change its rolling direction.

The four-wheel drive robot chassis is a mobile platform that uses four independently driven and steered wheels. It achieves omnidirectional movement and on-the-spot turning through four independent motors and steering mechanisms. It is mainly used on paved roads and some light off-road scenarios, and can handle complex terrains such as slopes, gravel roads, and muddy ground. It is especially suitable for scenarios that require high-precision navigation and obstacle avoidance.

Four-wheel drive: Refers to a 4wd smart robot chassis where all four wheels are equipped with independent drive motors. Each wheel can be independently controlled for speed and steering (forward or reverse), providing powerful traction and precise speed control.

Four-wheel steering: This refers to a chassis where all four wheels have independent steering mechanisms (typically steering wheels or hub motors). Each wheel can independently and at a large angle (typically continuous rotation from 0° to 360°) change its rolling direction.

Parameter Table

| Applicable venues | Indoor and outdoor complex road conditions in multiple scenarios (asphalt roads, grass, gravel roads, epoxy flooring, obstacle crossing, climbing slopes) |

| Sports mode | Four-wheel drive (omnidirectional mode) |

| Model | 4wd smart robot chassis kit |

| Dimensions | 960*550*395mm |

| Load capacity | 150KG |

| Speed (full load test) | 5.4km/h |

| Empty load range | 32km |

| Drive motor | 600W*2 |

| External power supply | 12V/15A-24V/15A-48V/10A |

| Braking method | Motor braking |

| Parking method | Electromagnetic brake, motor parking |

| Water depth | 50mm |

| Maximum climbing angle | No load 30°/Full load 10° |

| Crossing width | Full load 120mm/No load 150mm |

| Obstacle height | Full load 40mm/No load 60mm |

| Communication method | CAN 2.0B |

| Battery capacity | 48V/27AH |

| Charging time | 3h |

| Charging method | 48V/10A Manual charging/Automatic charging |

| Protection rating | IP44 |

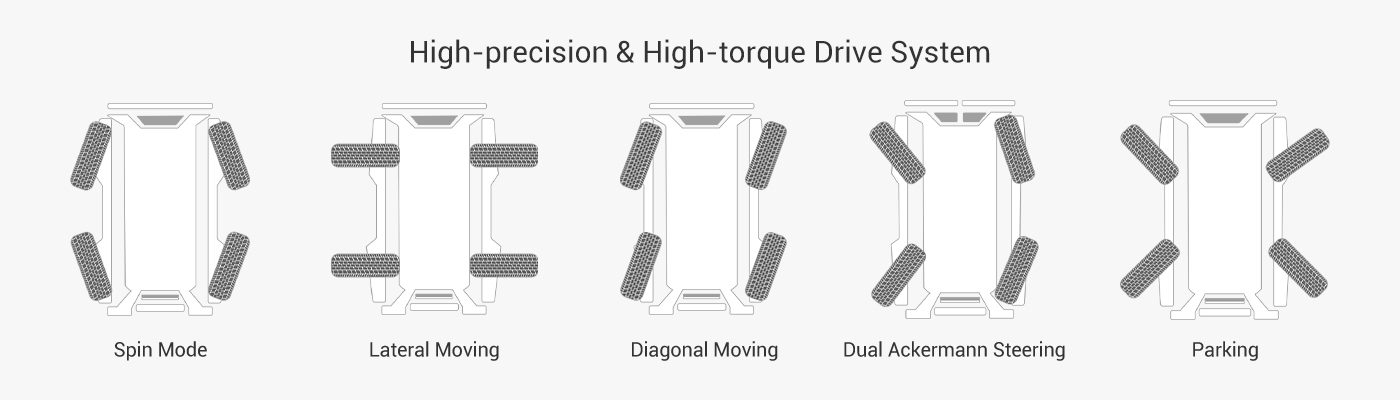

Omnidirectional mobility: By precisely controlling the drive direction and steering angle of the four wheels, the smart robot chassis can achieve:

Translation in any direction: forward, backward, lateral (sideways) movement, and diagonal movement.

Rotation in place: 360° rotation around the chassis center point (or any designated point) without moving forward or backward.

Composite motion: Simultaneously execute translation + rotation (e.g., along a circular path), with a continuous and smooth motion trajectory, eliminating the “zigzag” motion typical of traditional vehicles.

Zero turning radius: Synchronously adjust the steering angles of all four wheels (e.g., all pointing toward the center), with opposing drive directions, to achieve a 360° on-the-spot rotation around the 4 wheel smart robot chassis' geometric center or any designated point.

High-precision positioning and path tracking: Independent drive and steering control, combined with advanced navigation algorithms (such as laser SLAM and visual SLAM), enable the robot chassis to move along the planned path with high precision, even achieving micron-level positioning accuracy (in specific application scenarios).

Strong terrain adaptability and stability: Four-wheel independent drive provides better traction and maneuverability (especially on slightly uneven terrain). Independent steering allows the wheels to adjust their direction during turns to adapt to the path, enhancing stability.

Strong load-bearing capacity with uniform weight distribution: All four drive wheels share the load, enabling the robot to carry heavier cargo compared to a two-wheel drive, two-wheel steering configuration, while ensuring more even weight distribution.

Redundancy: Even if one wheel fails (under advanced control systems), the remaining wheels may still provide some mobility (though performance may be reduced), enhancing the system's robustness.

Complex Terrain Scenarios

Rugged Mountainous Terrain: The four-wheel independent drive and steering system can handle steep slopes, gravel roads, and other complex terrains. The independent drive system dynamically distributes power to the wheels with the best traction, preventing single-wheel slippage or getting stuck. At the same time, the steering mechanism adjusts the rolling direction of each wheel in real time to ensure precise path tracking on bumpy roads.

Muddy Rainforests: The tire surface features a special tread pattern that quickly expels mud and water, reducing the risk of slipping. Combined with an anti-slip design, it maintains traction in wet and slippery environments.

Frozen Polar Regions: In the extreme cold of frozen polar regions, the 4wd smart robot chassis enhances steering precision through a low-temperature optimized motor system and precision encoder design, adapting to icy surfaces in cold conditions.

Narrow Space Operations

Warehouse/Factory: Omnidirectional mobility (lateral, diagonal movement, and on-the-spot turning) reduces the turning radius, making it suitable for operations in narrow areas.

High-Load Tasks

Inspection/Transportation: With a load capacity of over 100kg, it can carry equipment such as robotic arms and cameras to perform heavy-duty tasks.

Unmanned forklift/tractor: Differential + steering wheel drive, load capacity increased to 200kg or more, suitable for medium to heavy-duty material handling.

Related Accessories

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +