Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

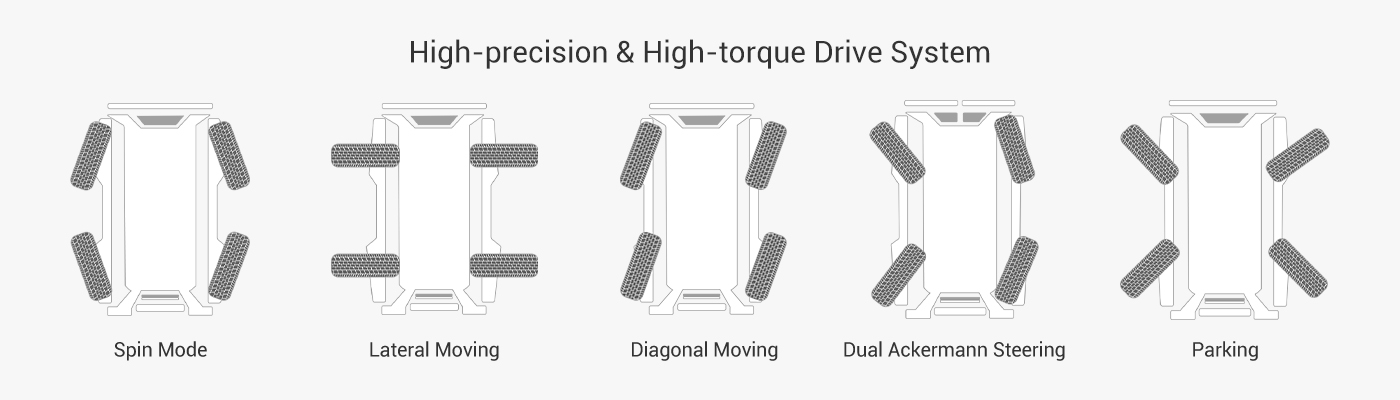

The four-wheel steering and four-wheel drive (4WS4WD) robot chassis adopts a modular architecture, with core components including the chassis frame, mounting components, drive mechanism, and wheels. Based on this, the chassis typically features independent drive and steering for all four wheels, supporting multiple steering modes (such as on-the-spot turning, zero-radius on-the-spot turning, diagonal driving mode, and parallel parking mode), enabling precise control and excellent off-road performance. It can also be equipped with various sensors and devices such as lidar and robotic arms, effectively addressing the challenges of unstructured terrain in scenarios such as industrial inspections, disaster rescue, agriculture, and transportation.

The four-wheel steering and four wheel drive (4WS4WD) robot chassis adopts a modular architecture, with core components including the chassis frame, mounting components, drive mechanism, and wheels. Based on this, the chassis typically features independent drive and steering for all four wheels, supporting multiple steering modes (such as on-the-spot turning, zero-radius on-the-spot turning, diagonal driving mode, and parallel parking mode), enabling precise control and excellent off-road performance. It can also be equipped with various sensors and devices such as lidar and robotic arms, effectively addressing the challenges of unstructured terrain in scenarios such as industrial inspections, disaster rescue, agriculture, and transportation.

Parameter Table

| Type | Medium four-wheel drive robot platform | |

| ● Standard configuration ○ Optional configuration - Not available | ||

| Chassis Specifications | Energy type | Pure electric (lithium iron phosphate battery) |

| Length*Width*Height(mm) | 3250*1670*660 | |

| Minimum ground clearance(mm) | 160 | |

| Minimum turning radius(m) | 3.5 | |

| Maximum fording depth(mm) | 160 | |

| Maximum obstacle clearance height(mm) | 120 | |

| Maximum climbing angle(%) | 20 | |

| Maximum speed(km/h) | 60 | |

| Curb weight(kg) | 700 | |

| Maximum payload(kg) | 1000 | |

| Battery and Charging | Battery capacity (kWh) | 16.1 |

| Range on empty (km) | 130 | |

| Slow charging time (hours) | 6 | |

| Wireless Drive Parameters | Drive type | Four-wheel distributed drive |

| Motor rated/peak power (kW) | 4*4 | |

| Motor rated/peak torque (Nm) | 31/180 | |

| Smart Hardware Features | OTA remote updates | ● |

| Backend data monitoring system | ● | |

| Remote start/stop | ● | |

| Tire pressure monitoring | ● | |

| Four-wheel speed detection | ● | |

| Hill start assist/hill descent control | ● | |

| Low speed alert | - | |

| Emergency stop button | ● | |

| Independent front/rear touch bar emergency stop | - | |

| Remote control | ● | |

The main components of a four-wheel drive chassis include the following:

Robot chassis frame: Serves as the supporting structure for the entire chassis, connecting and securing all parts, and withstanding dynamic loads.

Motors: Typically equipped with four independent motors (steering wheel and hub motors), each motor drives one wheel to achieve four-wheel drive and steering.

Motor drivers and controllers: Responsible for receiving commands, controlling motor operation, and achieving precise speed and steering control.

Wheels and tires: Four drive wheels support on-the-spot steering, zero-radius on-the-spot turning, diagonal movement mode, and parallel movement.

Sensors and auxiliary equipment: May include collision sensors, obstacle avoidance sensors, and lidar, used for environmental perception and control assistance.

Other components such as shock absorption modules and connectors, ensure chassis stability and shock absorption performance.

The four wheel drive robot chassis is suitable for indoor and outdoor applications, including:

The drive robot chassis offers high maneuverability, precise control, strong adaptability, and efficient path planning in indoor environments, making it particularly suitable for narrow, complex, or dynamically changing indoor scenarios:

Industrial plant inspection and transportation: Factory or warehouse environments often feature narrow corridors, oily or uneven floors, making them ideal for inspection tasks and material handling in factories or warehouses.

Robot chassis education and research: Research and educational environments require flexible testing of motion control and SLAM algorithms, making them ideal for experiments and teaching.

Indoor logistics and warehousing: Warehouse environments have narrow aisles and dense cargo, making this four wheel drive robot chassis highly suitable for flexible maneuvering and efficient path planning in confined spaces.

Outdoor environments present challenges such as unstructured terrain (muddy, rocky, steep slopes), dynamic obstacles, and harsh weather conditions:

Construction site operations: Used for material transportation or inspections. Construction sites feature unpaved roads, ditches, and temporary piles of building materials, creating a highly variable terrain. Traditional differential robot chassis are prone to getting stuck or losing steering capability in such environments.

Agricultural inspections and transportation: Suitable for complex farmland paths, ensuring efficient inspections and operations.

Energy industry applications: Such as inspections of power plants, oil fields, and other complex sites. Power plants/oil fields have flammable and explosive gases and high-temperature areas, making manual inspections risky.

Urban and industrial park patrols: With excellent off-road and steering capabilities, suitable for parks, industrial zones, and other variable terrains.

Light Off-Road Routes and Complex Terrain: Supports unpaved surfaces such as gravel and muddy terrain through a durable four-wheel drive system and excellent terrain adaptability.

This four wheel drive robot chassis features multiple movement modes (such as on-the-spot turning, sideways movement, and on-the-spot turning), enabling lateral movement and precise control in complex environments. It is equipped with shock absorption and independent suspension, enhancing ride smoothness and adaptability, making it particularly suitable for flexible operations across multiple industries and scenarios.

Related Accessories

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +