Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

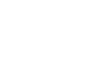

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

Wired Components

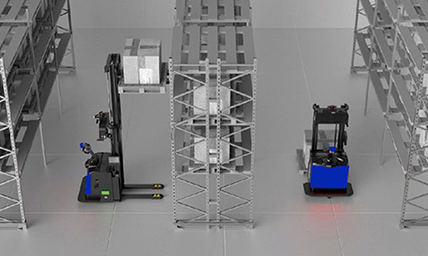

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Electric Motor Axle

Precision Drive, Smart Control for the Future

We offer a wide range of customization services, adjusting load capacity, power output, and layout according to customer needs. With a focus on high integration, rapid response, and intelligent adaptation, we meet the needs of industries such as autonomous driving, transportation, logistics, inspection, and firefighting.

We provide prototype testing + 3-year warranty — accelerate the implementation of your line control chassis with smarter drive solutions!

Description

The electric motor axle is the assembly located at the end of the transmission system in a steer-by-wire chassis, primarily consisting of the main reducer, differential motor, half-shafts, and drive axle housing. Its function is to transmit power from the transmission, reduce speed and increase torque, change the direction of power transmission, and distribute power to the left and right drive wheels, enabling the line-controlled chassis to move. It also bears part of the chassis weight, vertical road forces, driving forces, braking forces, lateral forces, and the bending moments and torques caused by these forces.

Drivetrains can be classified into integral axles (monolithic drivetrains) and split axles (disconnected drivetrains) based on their structural form. These two types of drivetrains have significant differences in structural design, functional characteristics, and application scenarios.

An integral axle refers to a design where the main reducer, differential, half-shafts, and other components are integrated into a monolithic axle housing. The connection between the axle housing and the wheels is rigid, with the entire axle housing serving as a single unit to bear the vehicle's weight.

A split axle refers to a design where the left and right wheels are connected to the vehicle body via independent suspension systems, with the half-shafts and differential housed in separate compartments. The axle housing is no longer an integrated unit but is instead split into separate sections.

The electric motor axle works in close coordination with the robot's suspension system to effectively filter out road vibrations, thereby enhancing the driving stability of the autonomous robot's chassis. Drivetrains with an integrated axle structure are typically paired with an integrated suspension system, offering high strength and stiffness, making them suitable for carrying heavy loads and handling harsh road conditions; Drivetrains with a split axle structure are often paired with an independent suspension system, enabling better adaptation to complex road conditions and providing superior handling performance.

Advantages and Selling Points

Drive shafts offer multiple key advantages in a variety of applications. Their modular design simplifies integration with various vehicles, while their efficiency ensures minimal power loss during energy transmission. In electric mobility vehicles, compact drive shafts enhance maneuverability in confined spaces, such as homes or crowded areas. For off-road vehicles, the robust axle is equipped with reinforced gears and impact-resistant performance, providing reliable performance on rugged terrain. Additionally, advancements in materials and engineering have reduced noise and vibration, enhancing user comfort.

The electric motor axle is a core component of a vehicle's power transmission system, and its structure varies depending on the application and drive type, but typically includes the following key components:

1. Differential

The differential is a crucial component of the drive axle, enabling the left and right drive wheels to rotate at different speeds when turning or driving on uneven surfaces. This functionality ensures pure rolling between the wheels and the ground, preventing abnormal tire wear and power loss, while significantly improving vehicle stability and maneuverability. When the vehicle turns, the differential automatically adjusts the rotational speeds of the left and right wheels based on factors such as the radius of the curve and vehicle speed, enabling the vehicle to smoothly navigate the curve while reducing the risk of body roll and loss of control.

2. Reducer

Its primary function is to reduce rotational speed and increase torque to meet the requirements of line-controlled chassis operation. Additionally, it can alter the direction of power transmission, converting the longitudinal direction of power output from the transmission into the lateral direction of power to the driven wheels.

3. Driveshaft and Coupling

The key components for transmitting motor power to the wheels. In a central drive system, the driveshaft may be connected to the motor and differential via a coupling (such as a universal joint).

4. Integrated Braking System

The drive axle and braking system (such as drum brakes or disc brakes) are designed as an integrated unit, with the brakes directly acting on the drive shaft or hub of the drive axle to ensure coordination between power transmission and braking.

5. Drive Axle Housing

The electric motor axle housing serves as the mounting base for components such as the main reducer, differential motor, and half-shafts. It also承受s vertical forces, driving forces, braking forces, and lateral forces transmitted from the road surface, as well as the bending moments and torques caused by these forces.

6. Suspension connection point (optional)

In vehicles that need to adapt to bumpy roads (such as off-road vehicles or logistics vehicles), the drive axle housing can be designed with suspension system connection points that absorb shocks through shock absorber springs or swing arms, improving driving stability.

Argumet

| Motor Type | Rear Axle Assembly Motor Conversion Kit |

| Tire Diameter | 35/40/45/50cm Wheel (Can be customized) |

| Rear Axle Length | 60cm-120cm (Can be customized) |

| Power Type | 800w-1500w (Can be customized) |

| Load Capacity | 500-800kg |

| Voltage | 48V/60V/72V |

| Rated speed | 35km/h |

| Weight | 40KG |

| Waterproof Grade | IP40 |

Applications

Drive shafts are not only used in autonomous robot chassis, but also in a variety of vehicles, including electric four-wheelers, food trucks, flatbed trucks, small trucks, sightseeing vehicles, parade floats, golf carts, off-road vehicles, and go-karts, among others.

The electric drive axle is not exclusive to autonomous robot chassis but is used in various vehicles and applications, highlighting its versatility and importance in electric vehicle systems. These include:

Autonomous Robot Chassis

Autonomous robots transmit driving instructions via electronic signals. The drive axle can precisely control motor output torque based on these signals, enabling precise control of vehicle speed to meet different driving conditions.

Golf Carts

Used to transport golfers and their equipment on golf courses, the drive shaft provides the necessary power and control to ensure smooth movement on grassy terrain (Parvalux).

Electric Trailers

Used for towing applications, such as for recreational or industrial purposes, where electricity is prioritized for environmental or operational reasons, ensuring efficient power transmission to achieve towing capability.

Electric Mobility Scooters

Critical for assisting elderly or mobility-impaired individuals, enabling independent movement across various environments from indoor to outdoor settings.

Warehouse and Logistics Vehicles

Used in warehouses and distribution centers for efficient goods transportation, with drive shaft reliability ensuring consistent performance under load.

Lawn Mowers

Especially electric models, where the drive shaft powers the cutting mechanism, providing quiet and efficient operation for residential or commercial use.

Off-road Vehicles

Some electric off-road vehicles utilize the drive shaft for powerful power transmission, capable of handling rugged terrain while providing stability and control.

Karting

Electric karts use the drive shaft to control speed and handling, suitable for racing or recreational purposes, where performance and responsiveness are critical.

Product Classification

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +