Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

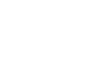

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

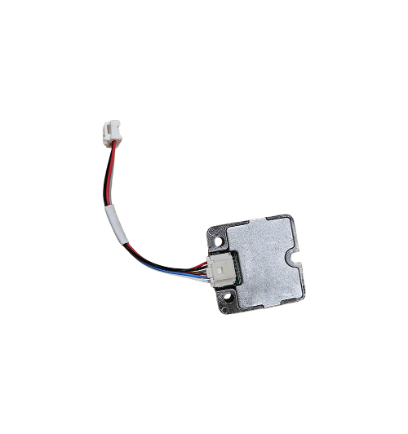

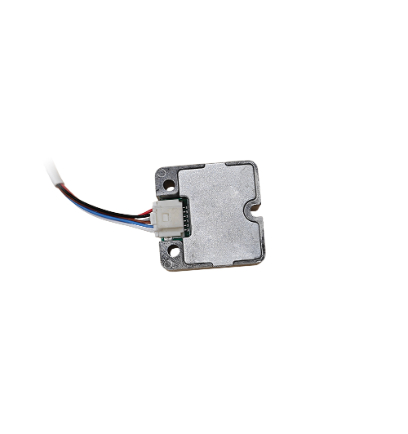

Inertial Measurement Unit

The IMU (inertial measurement unit) plays a central role in sensor systems for motion sensing, and is mainly used to measure the acceleration, angular velocity, and attitude changes of objects. Typically, it works in conjunction with other sensors (such as GPS, cameras, and LiDAR) to enable higher-accuracy motion tracking, navigation, and control systems.

IMU helps track a robot’s movement and posture by providing real-time data that maintains balance during motion, and assists in determining the robot’s position and orientation, especially in indoor or GPS-denied environments.

By delivering high-dynamic orientation awareness and autonomous motion feedback, IMUs play a key role in the following areas:

Localization and Navigation

Maintaining basic positioning capabilities in GPS-denied or feature-scarce environments.

Attitude Control

Dynamically adjusting chassis balance to accommodate rough terrain, inclines, or high-speed movement.

Environmental Adaptability

Maintaining stable operation under extreme temperatures, vibration, and varying lighting conditions.

Safety Protection

Detecting collisions, drops, or abnormal movements and triggering emergency response mechanisms.

Features

The application of IMU (inertial measurement unit) in robot chassis is very important, and its core features directly serve the robot's positioning, navigation, attitude control, and dynamic response capabilities.

1. Real-Time Attitude Sensing and Control

3D Attitude Calculation: The IMU uses accelerometers and gyroscopes to measure the chassis’ pitch, roll, and yaw angles in real time, helping the robot determine its own orientation, such as whether it is tilting, slipping, or experiencing uneven terrain.

Example: Preventing wheeled robots from tipping over on slopes or slippery surfaces.

2. High-Precision Motion Trajectory Estimation (Dead Reckoning)

Relative Localization Ability: In GPS-denied indoor environments (e.g., warehouses, underground tunnels), the IMU estimates displacement, velocity, and directional changes by integrating acceleration data. This provides an initial motion model for SLAM (Simultaneous Localization and Mapping).

Note: Long-term use may result in cumulative errors (requires fusion correction with wheel speed encoder, vision, or lidar).

Short-Term High-Dynamic Response: For fast-moving or frequently turning robots (e.g., AGVs, racing drones), the IMU’s high sampling rate (100–1000 Hz) captures instantaneous motion changes, improving trajectory prediction accuracy.

3. Environmental Adaptability and Robustness

Interference resistance: IMU does not rely on light, magnetic fields, or visual features, making it suitable for harsh environments such as darkness, dust, rain, and snow (e.g., industrial inspection robots and disaster relief robots).

Comparison: Visual navigation may fail in low-light conditions, whereas an IMU can still provide fundamental motion data.

Vibration and Shock Tolerance:Robot chassis equipped with industrial-grade or tactical-grade IMUs (e.g., specialized robots, unmanned vehicles) can maintain data stability even on bumpy roads or during intense movement.

4. Core Component for Multi-Sensor Fusion

Complementary to wheel speed encoders: IMUs compensate for errors in wheel speed encoders during slippage or suspension (such as when tracked robots slip on muddy ground) by fusing data through Kalman filtering to improve positioning reliability.

Assisting SLAM Systems: In laser SLAM or visual SLAM, the IMU provides motion prior information (such as rotation angles and acceleration) which helps reduce feature matching errors and accelerates map building and localization convergence.

Collaboration with GPS: For outdoor robots (e.g., agricultural robots, autonomous vehicles), when GPS signals are briefly lost (e.g., in tunnels or forests), the IMU can provide short-term inertial navigation to maintain continuous positioning.

5. Power Consumption and Miniaturization Compatibility

Lightweight design: MEMS IMUs are compact (e.g., the MPU6050 chip weighs only a few grams) and suitable for integration into lightweight robot chassis (e.g., floor cleaning robots, service robots) without affecting the overall weight distribution.

Energy efficient: Low-power IMUs are suitable for battery-powered mobile robots, extending battery life, especially for long-term tasks (such as inspections and logistics transportation).

6. Key Capabilities in Special Scenarios

Slip Detection: By monitoring sudden changes in chassis acceleration and angular velocity, the IMU can detect wheel or track slippage and changes in ground friction (e.g., adjusting power output when a tracked robot is climbing a slope).

Collision and Drop Response: The IMU detects abnormal accelerations or angular velocities (e.g., when a robot falls down stairs or collides with an obstacle), triggering emergency braking or posture protection mechanisms.

Terrain adaptability analysis: Through acceleration frequency domain analysis (such as FFT processing), determine ground roughness (flat, gravel, steps), and assist the chassis suspension system or gait planning.

Applicable Environments

IMUs (inertial measurement units) are capable of adapting to a variety of complex environments, particularly in robot chassis applications, due to their autonomy, high dynamic response, and strong environmental adaptability.

Logistics Warehouse Robots

In densely shelved areas, IMUs compensate for slip errors in wheel encoders using posture data, improving positioning reliability. They also detect vibration frequencies on uneven surfaces to optimize shock absorption systems.

Factory Line Inspection Robots

In high-temperature and strong electromagnetic interference environments, IMUs provide stable attitude feedback to assist precise positioning of robotic arms. They can also monitor abnormal vibrations (e.g., equipment failure) and trigger alarms.

Agricultural Spraying Robots

By detecting chassis posture on uneven terrain (e.g., slopes, ditches), IMUs help adjust spraying height. Acceleration data is used to determine whether wheels are stuck in muddy ground.

Orchard Harvesting Robots

On bumpy terrain, IMUs help maintain stable operation of robotic arms and support coordinated multi-joint movements.

Disaster Response Robots

In rubble or smoke-filled environments, IMUs enable autonomous posture control to prevent rollover. They also detect impact forces from obstacles to help plan escape routes.

Deep-Sea Exploration Robots

In GPS-denied, high-pressure underwater environments, IMUs assist in navigation and posture adjustment. They detect posture changes caused by water currents to stabilize robotic arm operations.

Nuclear Radiation Inspection Robots

In high-radiation environments, IMUs replace human inspections by providing reliable motion monitoring, ensuring accurate remote control. motion or displacement.

Ultrasonic Radar Array

By arranging multiple sensors in overlapping coverage patterns (e.g., 4–12 radars in a circular layout around the chassis), blind spots are reduced and lateral positioning accuracy is improved.

GPS / BeiDou Positioning

Satellite-based systems provide global positioning data, useful for outdoor applications such as agricultural robot navigation.

Product Classification

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +