- Home

-

About Xspirebot

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

-

Projects

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

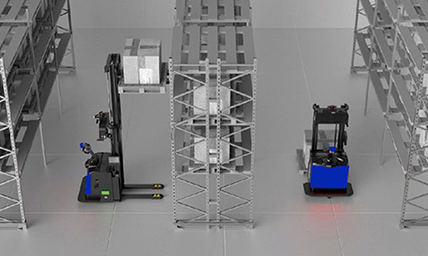

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

-

EV - Parts

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

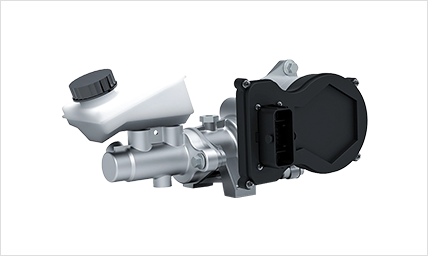

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

- System

-

News

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

- Contact Us

- Online Shop