Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

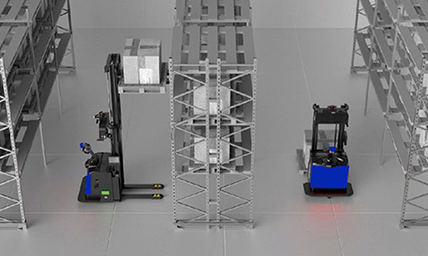

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

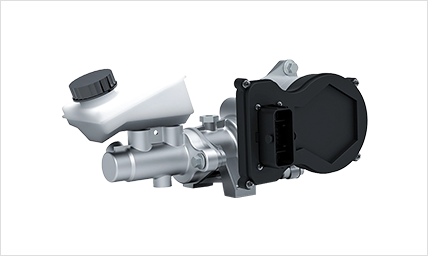

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

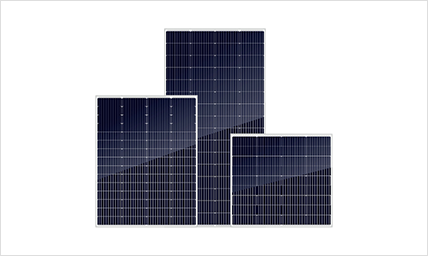

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Solar Panel

A solar panel, also known as a photovoltaic module, is a device that directly converts sunlight into electrical energy. It provides renewable energy support for robot chassis, reducing energy consumption costs and extending range through the roof or chassis. Its core principle is based on the photovoltaic effect of semiconductor materials: When photons strike the surface of a semiconductor, the energy is sufficient to excite electrons and form a current, generating direct current (DC).

Advantages of Solar Panels

Extended Battery Life

On sunny days, solar panels can generate an average of 50-150Wh of energy per day (depending on power output and sunlight intensity), reducing the frequency of charging.

Reduced Energy Costs

By utilizing solar energy to replace grid power, solar panels are ideal for deployment in remote areas (e.g., agricultural robots, outdoor inspection robots, logistics delivery robots, etc.).

Environmental Benefits

Zero carbon emissions, compliant with ESG (Environmental, Social, and Governance) standards.

Core Components of Solar Panels

Solar panels consist of the following key components, which work together to achieve efficient photovoltaic conversion and long-term stability:

Solar Cells: The core components that directly convert light energy into electrical energy.

Glass Layer: Protects the cells from mechanical damage and environmental corrosion while ensuring high light transmittance (>90%).

EVA Film: Bonds the cells, glass, and backsheet, providing insulation and cushioning protection.

Backsheet: Blocks moisture, UV rays, and mechanical impacts, providing electrical insulation.

Aluminum Alloy Frame: Secures the structural components, enhancing wind pressure resistance and load-bearing capacity (2,400 Pa wind pressure resistance, 5,400 Pa load-bearing capacity).

Junction Box: Collects current and connects to external circuits, with built-in diodes to prevent reverse current (“hot spot effect” protection).

Argumet

| Type | SKT 100M12 | SKT 200M12 |

| Maximum power | 100 | 200 |

| Open-circuit voltage | 22.3 | 44.61 |

| Short-circuit current | 5.44 | 5.57 |

| Operating voltage | 19.2 | 38.4 |

| Operating current | 5.21 | 5.21 |

| Efficiency | 21.08 | 21.79 |

| Dimensions | 620*765*25mm | 1200*765*30mm |

| Weight | 5.15kg | 9.4kg |

Applicable Environments

The application of solar panels in robot chassis requires precise matching of component types and system design based on environmental characteristics. Example scenarios:

Agricultural plant protection robots

equipped with solar panels continuously recharge while working in the fields, increasing the duration of a single task by 30%.

Outdoor inspection robots

equipped with sun-tracking gimbals increase power generation by 40% and can still maintain 12 hours of battery life in desert environments.

Desert exploration robots

equipped with 300W monocrystalline silicon modules + tracking systems generate an average of 1.5 kWh per day, maintaining 85% power generation efficiency at 50°C, and can operate continuously for 7 days without manual charging.

Logistics delivery robots

use 200W flexible solar panels, generating an average of 0.8 kWh per day, with a 25% increase in runtime in cloudy conditions, and achieve fully automated charging via wireless charging.

Factory inspection robots

are equipped with 150W monocrystalline silicon modules, maintaining 75% power generation efficiency at 60°C in factory workshops. Combined with lithium-ion batteries, they can perform continuous inspections for 12 hours, reducing the need for human intervention.

Product Classification

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +