Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

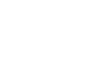

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

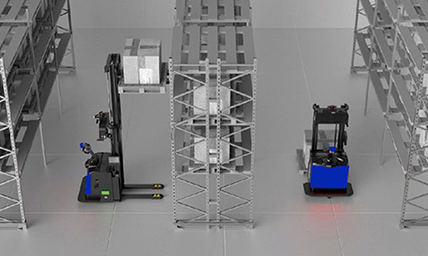

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Hub Motor

Xspirebot Hub Motor deeply integrates power, transmission, and braking systems within the wheel hub, achieving zero transmission loss through direct drive technology. Equipped with high-resolution encoders, it provides real-time speed and torque feedback for millimeter-level motion control—making it a productivity multiplier for autonomous robots in smart logistics, precision agriculture, and intelligent cleaning systems.

Claim for《Hub Motor Selection & Application Guide》

Download our free industry case studies collection + One-on-One Technical Consultation ➔ Apply now

Description

Hub motor integrates the motor, transmission, and braking systems directly within the wheel hub, achieving vehicle propulsion through direct rotation of the wheel.

For autonomous robots , this means transforming traditional wheeled platforms into electric systems that significantly enhance precision and efficiency in tasks such as warehouse logistics, agricultural machinery transport, industrial cleaning, and service delivery. Hub motors with encoders are particularly ideal for mobile robot platforms, offering optimized load and speed capabilities tailored for autonomous operations.

Customization Range

Our company offers a range of customizable hub motor options to meet the design and user requirements of various electric hand trucks, electric flatbed trucks, and autonomous robot chassis. We provide customizable options for motor size, voltage, power, torque, speed, and encoders, enabling you to select the most suitable hub motor based on different load capacities and terrain conditions.

Wheel Size Customization:

The hub motor is built directly into the wheel itself, so the customization options extend to wheel diameter and type. Typically ranging from 6 to 21 inches, the wheel size can be customized according to the structure of the autonomous robot chassis. Smaller wheels are suitable for compact chassis designed to operate in tight spaces, while larger wheels enhance stability and traction on rough terrain. Tires are available in pneumatic, tubeless, and solid types, and can be selected based on the application scenario. Additionally, tread patterns and materials can further complement the performance of the motor, enhancing grip or durability as required.

Rated Power: Typically ranges from 250W to 2000W or higher, depending on the intended load and terrain.

For autonomous robot chassis, hub motor power ranges from 250W for lightweight models (suitable for small-load vehicles such as patrol robots) to 750W or even 1000W for industrial-grade transport robot chassis (used in applications such as transportation and spraying that require handling heavier loads).

The power level directly affects the motor's ability to bear weight and resist stalling under load. We recommend selecting a motor whose power rating matches the expected payload of your robot chassis.

Voltage Options: Compatible with various battery systems and can be customized according to the battery system of the autonomous robot chassis. Common options include 24V, 36V, and 48V etc.. This customization ensures optimal matching between the motor and battery, allowing the motor to perform at its best.

Speed Settings: Can be adjusted via the controller to balance torque and efficiency. The range typically extends from 15 km/h for light-load applications to slower, high-torque configurations for heavy-duty tasks. With customization, users can prioritize greater traction — geared hub motors use internal planetary gears to increase torque, making them more suitable for steep slopes or heavy loads. The controller can also be programmed with variable speed settings, allowing users to switch between modes (e.g., low-speed/high-torque for towing vs. high-speed/low-torque for transportation).

Working Principle

The working principle of a hub motor is to drive the wheel directly through the rotation of the motor. When the battery pack supplies power to the hub motor, the magnetic field generated by the stator interacts with the magnetic field of the rotor, producing torque that causes the hub to rotate, thus propelling the vehicle forward.

To meet the speed and torque requirements of vehicle operation, hub motors are typically equipped with a reducer (gear), which converts the motor's high-speed, low-torque output into low-speed, high-torque output.

Advantage

Advantages of Hub Motors: When integrated into autonomous robot chassis—especially those designed for mobility applications—hub motors offer several practical advantages:

1. Hub motors enable independent wheel control. This allows for precise movement, including zero-radius turns, lateral movement (crab walking), and high-precision path tracking, which is critical for navigating complex or narrow environments.

2. Built-in encoders (such as Hall effect sensors) provide accurate position and speed feedback. This is essential for autonomous navigation and task execution, enabling precise path planning and obstacle avoidance.

3. Hub Motor integrated design (with motors embedded in the wheels) simplifies the overall structure, reduces the number of components, and makes maintenance easier by minimizing potential points of failure. This space efficiency is critical for robots with limited internal space, allowing more room for sensors, batteries, or other components.

4. High Precision Control and Positioning:When used with advanced control systems, hub motors offer highly accurate speed and torque control. This is crucial for autonomous robots that need to perform tasks requiring exact positioning and smooth movement, such as object manipulation or precision navigation.

5. Energy Efficiency:Direct-drive systems minimize energy loss during transmission, making hub motors an environmentally friendly choice. This is particularly important for battery-powered autonomous robots, as it helps extend their operational runtime.

6. The modular nature of hub motors allows for greater flexibility in chassis design. Robots can be easily configured with different numbers or sizes of wheels to meet specific application requirements.

Example: In AGV (Automated Guided Vehicle) steering drives, the brake is typically disabled when the motor speed exceeds 100 RPM to prevent unintended movement. Additionally, the brake can provide a smooth transition during equipment startup or shutdown, reducing mechanical shock and wear, thereby extending the service life of the equipment.

Steering Experience: The steering of a swivel wheel is based on differential drive, where the left and right wheels can rotate independently to achieve turning. When the vehicle needs to change direction, the steering drive unit turns left or right, altering the differential ratio between the wheels. This causes the left and right wheels to move at different speeds, resulting in a change in the vehicle's direction.

Parameter

| 10 Inch Electric Wheel Hub Motor | |

| Max Torque | 100 N.M |

| Rated Power | 500W |

| Rated Voltage | 24V36V/48V(default) |

| No-load Current | <1.5A |

| Pole Pairs | 10 |

| Gear Ratio | 5 |

| Speed | 7-10 km/h (48v 220RPM low speed) |

| Load Weight | 200-300kg |

| Motor Weight with Tire | about 7kg |

| 12 Inch Geared Hub Motor | |

| Max Torque | 100 N.M |

| Rated Power | 500W |

| Rated Voltage | 24V36V/48V(default) |

| No-load Current | <1.5A |

| Pole Pairs | 10 |

| Gear Ratio | 5 |

| Speed | 10-12 km/h (48v 220RPM low speed) |

| Load Weight | 150-250kg |

| Motor Weight with Tire | about 7kg |

| 13 Inch High Torque Hub Motor | |

| Rated Voltage | 48VDC |

| Rated Power | 500W/1000W |

| Max Torque | 100N.M/150N.M |

| Max Speed | 200RPM |

| Gear Ratio | 5:1 |

| Brake Type | Disc Brake |

| Shaft Type | Single Shaft/Double Shaft |

| Open Size | 155mm |

| Tyre Model | 4.00-8 |

| 16 Inch BLDC Hub Motor | |

| Rated Voltage | 48VDC |

| Rated Power | 500W/1000W |

| Max Torque | 100N.M/150N.M |

| Max Speed | 200RPM |

| Gear Ratio | 5:1 |

| Brake Type | Disc Brake |

| Shaft Type | Single Shaft/Double Shaft |

| Open Size | 155mm |

| Tyre Model | 4.00-8 |

Applicable Environments

Industrial Automation and Logistics AGV

Autonomous Guided Vehicles (AGVs): Steering wheel motors drive Mecanum wheels or differential wheel systems to enable omnidirectional movement (lateral movement, diagonal movement, and on-the-spot rotation), meeting the high-density material handling requirements between warehouse shelves.

Unmanned Forklifts: Through independent steering control of all four wheels, precise stacking of goods, and flexible maneuvering in narrow aisles are achieved.

Special Equipment and Outdoor Robots

Fire Inspection Robot: IP65 protection rating and wide temperature range design suitable for high-temperature and smoky environments, supporting remote reconnaissance and material transportation in hazardous areas.

Agricultural Robot: High torque output to handle soft soil in fields, combined with GNSS navigation to complete precise tasks such as planting and fertilization.

Security Inspection Robot: On-the-spot rotation function enables 360° blind-spot-free monitoring, suitable for perimeter patrols and response to abnormal incidents in industrial zones.

Product Classification

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +