Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

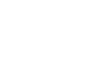

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

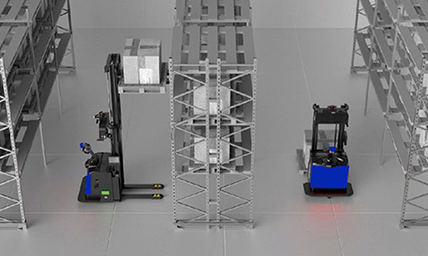

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Integrated Inertial Navigation System

Integrated Inertial Navigation System (IINS) is a comprehensive navigation technology that combines inertial navigation system with global positioning systems. Due to its high precision and real-time capabilities, Integrated Inertial Navigation System has become one of the core technologies enabling accurate positional awareness in applications such as smart devices, autonomous vehicles, and drones, by intelligently integrating multi-sensor data from GNSS (Global Navigation Satellite System) and IMU (Inertial Measurement Unit) to enable high-accuracy, high-reliability positioning solutions.

Working Principle

The fundamental principle of Integrated Inertial Navigation System lies in measuring an object's acceleration and angular velocity in space, then calculating its position, velocity, and attitude angles based on these measurements. The system's core concept is the synergistic integration of multi-sensor technologies, such as the Inertial Measurement Unit (IMU) and the Global Navigation Satellite System (GNSS), which mutually compensate for their individual limitations. This fusion enhances navigation accuracy and system stability, enabling reliable performance even in dynamic or signal-challenged environments.

Key Roles of IINS

1. Minimizes Error Accumulation in Single-Sensor Systems (e.g., integration drift in standalone IMUs or positioning gaps during GNSS signal outages).

Utilizes real-time fusion algorithms to calculate the robot chassis's position, velocity, and attitude (heading, pitch, roll) by integrating IMU-measured acceleration and angular velocity with GNSS and auxiliary sensor data.

Application Scenarios: Precision navigation solutions for robot chassis, autonomous driving, drones, and industrial automation systems requiring continuous high-accuracy spatial awareness.

2. Dynamic Disturbance Resistance (such as vibrations, signal obstructions, and electromagnetic interference)

In GNSS-denied or weak-signal environments (such as tunnels, underground area, urban canyons), the system maintains uninterrupted navigation by fusing IMU data with complementary sensors like odometers, vision systems, and LiDAR, and auto-recalibrates upon GNSS signal restoration,

Application Scenarios: Tunnels and underground facilities, Dense urban environments with high-rise buildings,Mountainous regions and GPS-challenged areas

3. Enhanced Dynamic Response

The high-frequency output of INS (above 100Hz) compensates for the low-frequency output of GNSS (1–10Hz), enabling precise capture of dynamic behaviors such as high-speed motion, sharp turns, and jolts experienced by the robot.

4. Reduced Reliance for Single Sensors and Cost

By integrating low-cost sensors (e.g., MEMS IMU, wheel encoders), the system achieves performance comparable to high-precision navigation systems, replacing expensive standalone inertial navigation devices (e.g., fiber optic gyroscopes).

5. Redundant Backup

Multi-sensor cross-redundancy ensures higher system reliability, designed for safety-critical applications (e.g., aviation, autonomous vehicles)

Advantage

1. High-Precision Navigation: One of the key advantages of an integrated inertial navigation system (IINS) is its ability to deliver high-precision navigation data. By integrating data from multiple sensors, such as GNSS, IMU, and odometer, the cumulative error of inertial sensors can be reduced, thereby achieving more accurate position and attitude estimation.

2. High Real-Time Performance: Since the combined inertial navigation system mainly relies on inertial sensor measurement data, its navigation information is updated in real time, accurately capturing the robot's high-speed movement status (such as sharp turns and bumpy terrain) to meet the closed-loop control requirements of autonomous driving. This makes the combined inertial navigation system play an important role in applications that require rapid response and instant decision-making, such as missile guidance and aircraft autonomous navigation.

3. Environmental Adaptability: In scenarios such as building roads, tunnels, urban canyons, and dense forests, GNSS signals may be affected and unable to provide accurate positioning.The inertial navigation system can maintain navigation capabilities through inertial measurement data, ensuring accurate navigation information and guaranteeing continuous and reliable robot operation.

4. Robustness Against Disturbances: The system features built-in sensor self-calibration and online error compensation algorithms (e.g., ZUPT [Zero Velocity Update] for drift correction and slip detection) to maintain long-term stability under challenging conditions such as vibration, temperature drift, and electromagnetic interference (EMI)

5. Enhanced Data Security: Integrated Inertial Navigation System rely exclusively on internal sensor measurements, offering superior confidentiality compared to GNSS-dependent solutions. This inherent security advantage makes them ideal for military applications where resistance to signal interception, jamming, and spoofing is critical.

6. Hardware Scalability: Supporting on-demand configuration of sensor types (such as low-cost IMU + odometer solutions) to meet the differentiated needs of AGV logistics robots, inspection robots, special-purpose robots, etc.

7. Multi-scenario Field Testing and Verification:TheIINS has undergone tens of thousands of hours of field testing in complex environments such as underground mines, urban roads, and power inspection, with an MTBF (mean time between failures) of ≥10,000 hours.

Integrated Inertial Navigation System workflow

1. Data Acquisition: The Inertial Measurement Unit (IMU) measures the object's linear acceleration and angular velocity, generating real-time inertial data.

2. Initial Alignment: Prior to navigation, the system undergoes initial alignment to calibrate baseline measurement errors (e.g., sensor biases, misalignment angles).

3. Data Fusion: Fusion of inertial measurement data with GNSS data, using filtering algorithms (such as Kalman filtering) to reduce measurement errors and obtain more accurate navigation information.

4. Continuous Updating: The combined inertial guidance system continuously integrates new inertial measurement data and GNSS data during operation to maintain navigation accuracy and stability.

Operating Environments

Integrated Inertial Navigation System deliver continuous, reliable navigation in complex, extreme, and dynamic environments through multi-sensor fusion and intelligent algorithm optimization. This makes them the core technology foundation for robotic platforms, aerospace systems, and specialized industrial applications. Key scenarios include:

GNSS-Denied Navigation

Warehouse Logistics Robots: Autonomous navigation for AGVs (Automated Guided Vehicles) in GNSS-denied indoor environments.

Industrial Inspection Robots: Equipment inspection at power plants and chemical plants.

Underground Mining Robots: Transporting ore in tunnels where GPS signals are limited, using laser radar/inertial navigation systems (LIDAR/INS) for transportation, geological exploration, and safety monitoring.

Subway Tunnel Inspection robots: Track measurement, Tunnel deformation monitoring

Weak GNSS signal environment

In scenarios such as “urban canyons” (where tall buildings block GNSS signals), high-density building areas, tunnels, and underground parking lots, GNSS signals may be unstable. In such cases, a combined inertial navigation system can ensure continuous positioning and stable Robot chassis navigation.

Dynamic and high-interference environments

Racing cars, drones, fighter jets, etc. need to maintain high-precision navigation in environments with strong interference and no GNSS signals.Combined inertial navigation systems can provide accurate navigation and positioning information in high-intensity battlefield environments.

Extreme Natural Environments

Integrated Inertial Navigation System enable precise navigation in GNSS-denied extreme environments—such as glaciers, deserts, and dense forests—by leveraging multi-sensor fusion and algorithmic optimization. These systems ensure reliable robotic operation in the following scenarios:

Polar Research Robots: Glacial Terrain Exploration

Desert Survey Robots: Arid Environment Mapping

Forestry Inspection Robots: Forest Fire Monitoring

Aerospace & Deep Space Exploration

When a spacecraft re-enters the atmosphere (communication is interrupted in the blackout zone), the combined inertial navigation system can provide accurate flight status and position information, which is helpful for the spacecraft's autonomous navigation, landing, and obstacle avoidance.

Specialized Industrial Applications

Integrated Inertial Navigation Systems enable safe, reliable navigation in hazardous industrial environments—such as cryogenic storage, explosive atmospheres, and corrosive chemical zones—through explosion-proof design, environmental resilience, and multi-sensor fusion. Key applications include:

Cold Chain Logistics Robots: Frozen Warehouse Auto-Sorting

Oil & Gas Pipeline Inspectors Robots: Explosive Atmosphere Monitoring

Chemical Plant Explosive-Proof Robots: Hazardous Zone Operations

Product Classification

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +