Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

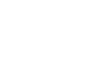

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

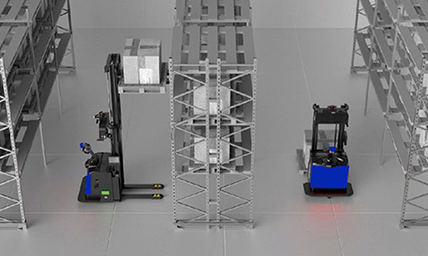

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

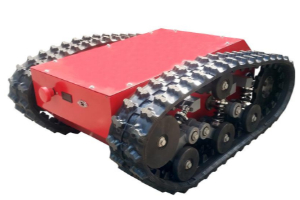

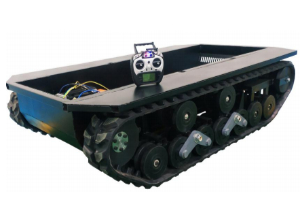

Tracked Chassis

A tracked chassis is a specialized piece of equipment distinct from a wheeled chassis, primarily used for operations in various complex terrains.It makes contact with the ground via tracks, providing a large contact area that offers strong traction and stability, making it suitable for muddy, steep slopes, gravel, snow, desert, mountainous, and other complex terrains.Compared to wheeled chassis, tracked designs offer superior off-road capability and load-bearing capacity, making them widely used in over 10 industries including security, disaster relief, industry, mining, agriculture, forestry, polar regions, and special environments.

Exceptional Terrain Adaptability

Low Ground Pressure: The wide contact area of tracks (e.g., typical robot ground pressure ranges from 20–50 kPa) significantly reduces the pressure exerted on the ground, enabling stable movement over soft surfaces such as mud, snow, and sand, preventing sinking.

Obstacle-Crossing Capability: The continuous rolling surface of tracks allows easy traversal over obstacles like rocks, ditches, and rubble. Slopes up to 30° can be climbed, and some specialized models are capable of vertically climbing steps up to 1 meter high.

Anti-slip design: The tread pattern on the surface of the track (such as the spikes on metal tracks or the raised patterns on rubber tracks) enhances friction with the ground, making it suitable for low-friction environments such as ice and wet slopes.

High Load-Bearing Capacity

Structural Load Distribution: The distributed support provided by the tracks spreads the vehicle’s weight evenly across the entire contact surface. A single track can carry hundreds of kilograms to several tons of load.

Power Matching: High-torque drive motors or hydraulic systems (e.g., brushless DC motors combined with planetary gearboxes) provide sufficient driving force, supporting the integration of heavy payloads such as robotic arms, sensor arrays, and rescue toolkits.

Excellent Stability and Rollover Resistance

Center of gravity distribution: The flat chassis design lowers the center of gravity of the entire vehicle. Combined with the wide track width structure, it greatly improves lateral and longitudinal stability and reduces the risk of overturning on steep slopes or uneven terrain.

Suspension System: Torsion bar / hydraulic suspension or elastic road wheel designs help absorb shocks, maintaining consistent track-to-ground contact and improving ride smoothness.

Dynamic Balance: The robot chassis integrates an IMU (Inertial Measurement Unit) and adaptive control system, which dynamically adjusts track speed in real time to maintain stable posture, for example, posture correction for earthquake rescue robots traversing rubble piles.

Strong Modularity and Expandability

Standardized Interfaces: The chassis includes pre-designed mounting holes, power interfaces (e.g., 24V/48V DC), and communication protocols (e.g., CAN bus, ROS-compatible interface), enabling rapid integration of upper equipment such as LiDAR, infrared cameras, and robotic arms.

Functional Adaptability: Supports customized modifications for various applications, including: Industrial Inspection--Integration of thermal imaging cameras or gas sensors.

Agricultural Use--Connection to spraying systems or soil analyzers.

Case Example

A firefighting robot chassis can switch between a "water cannon" module and a "heat source detection" module to meet different rescue scenarios.

Customization Options

Customizable dimensions, appearance, load capacity, and various development functions, enabling unmanned control, Beidou navigation, autonomous navigation, automatic obstacle avoidance, and automatic following. Customizable rubber tracks with various appearances, dimensions, embedded magnets, corrosion resistance, oil resistance, high temperature resistance, and anti-static properties can also be tailored to meet customer usage requirements and environmental conditions.

Suitable Ground Environments

1. Soft or Low-Bearing-Capacity Ground:Such as swamps, muddy areas, sandy terrain, snowfields, farmland, and wetlands.

The wide contact area of tracks significantly reduces ground pressure, preventing the vehicle from sinking. For example, tracked snow vehicles distribute their weight over a large surface area to avoid getting stuck in deep snow.

2. Rugged, hard terrain: mountains, rock piles, ruins, gravel roads, ravines, etc.

Tracks have a continuous rolling surface and strong obstacle-crossing capabilities, enabling them to climb slopes of 30° or more and cross obstacles up to 0.5 meters high (depending on chassis size and power).

3. Slippery or Low-Friction Surfaces: Ice, moss-covered ground, muddy roads after rain, oily surfaces, etc.

The treads on the track surface (such as cleats on steel tracks) provide enhanced traction and reduce slippage. For example, polar exploration vehicles use tracks equipped with ice claws to increase grip on icy surfaces.

4. Extreme High or Low-Temperature Environments:deserts, volcanic regions, polar areas, and permafrost zones.

High-Temperature Environments: Track materials (such as heat-resistant rubber or composite metals) can withstand extreme temperatures (e.g., surface temperatures in deserts can exceed 70°C).

Low-Temperature Environments: Cold-resistant rubber tracks or heating systems prevent material embrittlement (e.g., Arctic research robots can operate at temperatures as low as -50°C).

5. Areas with Dense Obstacles: Urban ruins, collapsed buildings, dense forests, and shrublands.

Tracked chassis have a low center of gravity and strong stability, allowing them to crush small obstacles (such as debris and branches) while reducing the risk of rollover. For example, rescue robots can navigate through rubble in post-earthquake disaster zones.

6. Environments Where Ground Damage Must Be Minimized: lawns, farmland, archaeological sites, and paved roads.

The low ground pressure of tracks minimizes damage to the surface (e.g., agricultural machinery tracks help protect soil structure). Some lightweight tracks (such as rubber tracks) can even travel short distances on asphalt without damaging the road surface.

7. Not Recommended Scenarios (Use with Caution)

Highways or Urban Roads: Tracks cause significant wear on hard surfaces and are speed-limited (typically off-road speed is below 20 km/h).

Confined spaces: Large turning radius (requires on-the-spot turning technology), less flexible than wheeled chassis.

Light Load and Short-Distance Transportation: Lower cost-effectiveness compared to wheeled systems; wheeled chassis are generally more suitable for such applications.

Components

The tracked chassis consists of complex and precision-engineered parts that work together to achieve high mobility, stability, and load-bearing capacity.

1. Track: The part that comes into direct contact with the ground. Its wide surface area distributes the vehicle's weight, reducing ground pressure.

Key Parameters: Width (affects ground pressure), pitch (distance between adjacent track plates), number of teeth (engages with the driving wheel).

2. Driving Wheel / Sprocket: Drives the track through gear transmission and serves as the core component for power delivery.

3. Idler Wheel: Adjusts the direction of the track and maintains proper tension, helping control vehicle steering.

4. Road Wheels: Support the vehicle’s weight and distribute pressure, reducing track deformation.

5. Track Roller: Prevents sagging or lateral deviation of the track, ensuring smooth and stable operation.

6. Suspension System: Absorbs shocks, maintains track-to-ground contact, and improves ride stability and comfort.

7. Power System (Engine & Transmission): Provides driving force and transmits it to the driving wheel via the transmission system.

8. Steering Mechanism: Enables vehicle steering, typically by adjusting the speed or direction of each side of the track independently.

Argumet

| Model | ZDDP-CF150 | ZDDP-PY180 | ZDDP-XF150 | ZDDP-XF100 | ZDDP-BJ100 | ZDDP-XHDX-150 | ZDDP-JY-150 |

| Image |  |  |  |  |  |  |  |

| Chassis length | 1000mm | 1800mm | 1000mm | 800mm | 890mm | 2010mm | 1000mm |

| Chassis width | 800mm | 1100mm | 770mm | 600mm | 600mm | 1460mm | 800mm |

| Chassis height | 350mm | 420mm | 350mm | 220mm | 280mm | 760mm | 380mm |

| Total chassis height | 350mm | 520mm | 240 mm (including housing) | 280 mm (including housing) | 760mm | 400mm | |

| Track width | 150mm | 180mm | 150mm | 100mm | 100mm | 150mm | 150mm |

| Track model | ZD-150 (plug gear) | ZD-180 (gear hobbing) | ZD-F150 | ZD-100 | ZD-100 | ZD-150 | ZD-150 |

| Standard motor | 48V-1500w | 48V-2500w | 48V-1500w | 48V-800w | 48V-1500w | 48V-2000w | 48V-1500w |

| Standard reducer | RV50 | RV63 | RV50 | RV50 | RV50 | RV63 | RV50 |

| Dual drive controller | 75A | Single drive controller: 120A | Dual drive controller: 75A | Dual drive controller: 75A | Dual drive controller: 75A | Dual drive controller: 120A | Dual drive controller: 75A |

| Standard | 2.4G wireless remote control set | ||||||

| Shock-absorbing chassis | Electric motor brake | Free suspension chassis | Shock-absorbing chassis | ||||

| Chassis weight | Approximately 150kg | Approximately 260kg | Approximately 160kg | Approximately 70kg | Approximately 70kg | Approximately 200kg | Approximately 150kg |

| Maximum load | 200kg | 500kg | 150kg | 100kg | 150kg | 200kg | 150kg |

Applicable Environments

Security Applications

Patrol Robots: Perform 24/7 monitoring and patrol missions in challenging terrains such as mountainous areas and jungles.

Explosive Ordnance Disposal (EOD): Tracked robots equipped with robotic armscan remotely dismantle bombs and other hazardous materials in dangerous environments

Disaster Rescue and Emergency Response

Earthquake/landslide rescue: Navigating through irregular environments such as rubble and debris, equipped with life detection instruments or communication devices to search for survivors.

Firefighting and Nuclear Radiation Detection: Designed to enter high-temperature or radiation-contaminated zones where human access is not possible, performing monitoring and initial response tasks.

Urban Counter-Terrorism Operations: Ideal for covert reconnaissance and intervention in narrow spaces or obstacle-dense areas.

Industrial and Mining Applications

Mine Exploration Robots: Used for geological surveys or material transportation in harsh environments such as underground mines and collapsed areas.

Power Line Inspection Robots: Perform automated inspections along steep terrain or complex industrial infrastructure, such as oil pipelines and substations.

Heavy Load Transport Robots: Autonomous tracked platforms for transporting large components in factories or warehouses.

Agriculture and Forestry Applications

Precision Farming Robots: Carry out tasks such as seeding and pesticide spraying in muddy fields or terraced farmland (e.g., Yanmar’s tracked agricultural robot from Japan).

Forest Fire Patrol Robots: Traverse dense forests and mountainous areas to monitor fire conditions in real time and transmit data.

Logging Assistance Robots: Transport timber or clear obstacles in rugged forest environments.

Polar and Special Environment Research

Polar Exploration Robots: Conduct meteorological monitoring or geological sampling on glaciers and snowfields where terrain with low surface traction (e.g., China's "Polar Rover" robot).

Volcano monitoring robot: Climbs volcano craters or lava fields to collect data.

Space Exploration Prototypes: Test mobility performance on simulated lunar or Martian terrain (e.g., NASA’s ATHLETE robot).

Product Classification

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +