Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

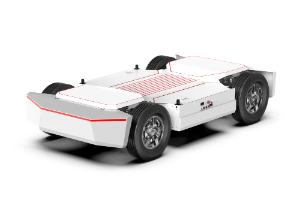

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Ackermann Chassis

Ackermann Robot Chassis: Precise Response to Various Terrains

The Ackermann chassis uses an Ackermann steering structure to achieve coordinated steering control of all wheels, supporting zero turning radius and dynamic path planning, enabling anti-skid and energy-efficient movement in various environments.

Its aluminum alloy frame, all-terrain tires, and IP67-rated components enable it to handle muddy farmland, polar regions, and other extreme conditions. It is ideal for agricultural spraying robots, power line inspection robots, and campus security patrols, ensuring minimal ground disturbance during sharp turns and seamless integration with LiDAR, thermal sensors, or AI navigation systems.

Contact us for a free consultation or download our industry use case white paper.

The Xspire chassis features a front and rear double Ackermann steering structure, enabling full-wheel coordinated steering control, supporting zero turning radius and dynamic path planning, and offering flexible handling. Based on a vehicle-grade CAN bus architecture, it deeply integrates drive, steering, braking, and parking systems, ensuring real-time and stable multi-module coordinated control.It also provides standardized CAN bus communication protocol interfaces, supporting user-defined development and functional customization.By mounting diverse upper-level components (such as cargo boxes, robotic arms, lidar, and visual sensors), it can quickly adapt to the following application requirements:

Intelligent Logistics and Warehousing: AGV autonomous transport vehicles, container handling equipment for ports

Outdoor Operations and Inspection: Agricultural spraying robots, power line inspection robots, campus security patrol robots.

Scientific Research and Education: ROS-based robot development platforms, motion control teaching labs, AI algorithm verification systems

High Steering Efficiency and Minimal Tire Wear

Pure Rolling Steering: By designing the inner and outer wheels to turn at different angles, the Ackermann chassis ensures that all wheels rotate around the same Instantaneous Center of Rotation (ICR) during a turn. This minimizes tire side-slip , significantly reducing wear and tear and enabling the robot to accurately follow planned paths (straight lines, arcs, or complex curves).

Extended Tire Life: Especially beneficial in applications involving frequent turning (e.g., logistics vehicles, agricultural machinery), this design greatly reduces abnormal wear caused by sliding , lowering maintenance costs and downtime.

Strong Stability and Low Energy Consumption

Low-Speed Agility: During parking or U-turns, the Ackermann geometry provides smoother handling , helping to prevent loss of control due to tire slippage.

Low energy consumption: Due to minimal tire side slip during steering, the Ackermann chassis has lower rolling resistance, making it particularly suitable for long-distance, high-frequency operation scenarios (such as warehouse AGVs and unmanned delivery vehicles), significantly improving battery life.

Simple structure, low maintenance costs

Pure mechanical design: relies on a trapezoidal link mechanism to achieve steering angle differences, without the need for complex electronic components, resulting in low failure rates and easy maintenance.

High cost-effectiveness: suitable for cost-sensitive models (such as robot chassis), without the need for additional investment in electronic steering systems.

Compatibility with Modern Technologies

Integration with Electric Power Steering (EPS): Sensors and motors can dynamically adjust steering angles (e.g., correcting path deviations), enabling active steering control that enhances obstacle avoidance and dynamic path planning capabilities.

Adaptability to Autonomous Driving: As the physical foundation for motion control, the Ackermann chassis ensures that steering trajectories align with geometrically optimal paths , supporting precise and efficient autonomous navigation.

Components

1. Steering System (Front and Rear Dual Ackermann Structure)

Front/Rear Ackermann Steering Mechanism: Based on a trapezoidal linkage mechanical structure, it enables differential steering angles between the inner and outer wheels (with a larger turning angle for the inner wheel), ensuring pure rolling during turns and minimizing tire wear.

Omni-directional Maneuverability: The dual front-rear Ackermann design supports complex motion patterns such as zero turning radius, diagonal movement , and on-the-spot rotation, enhancing agility and adaptability in tight spaces.

Steering Execution Unit: Equipped with high-precision servo motors or Electric Power Steering (EPS) modules, it receives steering commands via the CAN bus and adjusts the steering angle in real time to ensure precise control.

2. Drive System

Distributed Drive Units: Each wheel is equipped with an independent brushless DC motor (BLDC) or hub motor, delivering high torque output and precise speed control.

Differential Coordination Control: Adapts to varying wheel speeds under different turning radii, ensuring smooth and stable cornering performance.

Drive Controller (Motor Controller): Receives speed commands via the CAN bus and dynamically allocates driving power to each wheel, enabling efficient energy utilization and stable motion control under various operating conditions.

3. Braking and Parking System

Electronic Braking Module (E-Brake): Features independent electronic hydraulic braking on all four wheels, supporting emergency stop , hill hold parking , and regenerative braking. Integrated with Steering System, responds rapidly to path planning commands during emergency situations.

Parking Lock Mechanism: Equipped with mechanical or electromagnetic parking device , allowing remote control of robot positioning and secure parking via the CAN bus.

4. CAN Bus Control System

Central Control Unit (Vehicle Control Unit, VCU): An industrial-grade microprocessor or embedded controller, responsible for coordinates real-time interaction among the drive, steering, braking, and parking systems.

Pre-installed Control Algorithms: Includes fundamental control logic such as the Ackermann kinematic model and PID path tracking , while also supporting user-defined logic development for custom applications.

CAN Communication Interface: Provides standardized CAN 2.0B protocol stack and data frame definition, and opens up low-level control permissions (such as motor speed, steering angle, and brake pressure).

Integration with External Devices:

Supports seamless integration with external devices (such as lidar, vision sensors, and ROS systems).

5. Power Management System

High-Capacity Battery Pack: Equipped with lithium-ion batteries or supercapacitors to meet long-duration operational requirements under high-load conditions.

Intelligent BMS (Battery Management System): Real-time monitoring of voltage, current, and temperature to optimize charging and discharging efficiency while ensuring system safety and battery longevity.

6. Upper Component Expansion Interfaces

Standardized Mechanical Mounting Points: Pre-designed mounting holes for cargo racks, robotic arm bases, sensor gimbals, and other modules, enabling rapid integration for logistics, inspection, research, and other application scenarios.

Multi-Protocol Peripheral Interfaces: Supports a variety of physical interfaces including RS485, Ethernet, and GPIO, compatible with sensors such as LiDAR , IMU , GPS , and cameras. Software Development Kit (SDK):Provides CAN protocol parsing libraries, motion control APIs, ROS drivers, and sample code to significantly reduce the barrier for secondary development and customization.

7. Safety and Redundancy Design

Multi-Level Fault Protection Mechanism: Integrates hardware watchdogs and software heartbeat detection to prevent system out of control caused by communication interruptions or module failures, ensuring stable and safe operation.

Redundant CAN Network: Features a dual-channel CAN bus architecture , with independent communication channels for critical systems (steering and braking), significantly enhancing system reliability and fault tolerance.

Emergency Stop Button (E-Stop): A physical emergency stop switch directly connected to the main power circuit, supporting remote wireless triggering to ensure rapid and reliable response in emergency situations.

Working Principle

The Ackermann chassis is based on the Ackermann steering geometry, which uses a mechanical linkage to ensure that the inner and outer front wheels turn at different angles during a maneuver (inner wheel turning at a greater angle than the outer wheel).

This design allows all wheels to rotate around the same instantaneous center of rotation during a turn, minimizing tire sideways slip and wear, while improving steering efficiency and vehicle handling stability.

Argumet

| Model | W1 | W2 | W3 | W6 | W7 | |

|  |  |  |  | ||

| Type | Small rear-wheel drive robot platform | Compact front-wheel drive robot platform | Medium four-wheel drive robot platform | Medium six-wheel drive off-road robot platform | Medium rear-wheel drive robot platform | |

| ● Standard Configuration ○ Optional Configuration - Not Available | ||||||

| Chassis Specifications | Energy type | |||||

| Length*Width*Height(mm) | 2030*970*610 | 2540*1005*670 | 3250*1670*660 | 2365*1645*1335 | 3550*1300*650 | |

| Minimum ground clearance(mm) | 110 | 120 | 160 | 200 | 155 | |

| Minimum turning radius(m) | 2.5 | 3 | 3.5 | Pivot | 4.2 | |

| Maximum fording depth(mm) | 90 | 200 | 160 | 600 | 195 | |

| Maximum obstacle clearance height(mm) | 100 | 120 | 350 | 120 | ||

| Maximum climbing angle(%) | 50 | 20 | ||||

| Maximum speed(km/h) | 20 | 40 | 60 | 40 | ||

| Curb weight(kg) | 280 | 415 | 700 | 1480 | 620 | |

| Maximum payload(kg) | 500 | 685 | 1000 | 800 | 1080 | |

| Battery and Charging | Battery capacity (kWh) | 2.5 | 11.5 | 16.1 | 15.5 | 18.4 |

| Range on empty (km) | 60 | 100 | 130 | 110 | 150 | |

| Slow charging time (hours) | 2 | 2.5 | 6 | 4 | 4 Hour | |

| Wireless Drive Parameters | Drive type | Rear-wheel drive (RWD) | Rear-wheel drive (RWD) | Four-wheel distributed drive | Six-wheel distributed drive | Rear-wheel drive |

| Motor rated/peak power (kW) | 2.5/5 | 5/10 | 4*4 | 5*6 | 7.5/15 | |

| Motor rated/peak torque (Nm) | 11.5/45 | 14/65 | 31/180 | 12/60 | 24/90 | |

| Smart Hardware Features | OTA remote updates | ● | ● | ● | - | ● |

| Backend data monitoring system | ● | ● | ● | - | ● | |

| Remote start/stop | ● | ● | ● | - | ● | |

| Tire pressure monitoring | - | ● | ● | - | ● | |

| Four-wheel speed detection | - | ● | ● | ●(Six rounds) | ● | |

| Hill start assist/hill descent control | ● | ● | ● | ● | ● | |

| Low speed alert | - | ● | - | - | ● | |

| Emergency stop button | ● | - | ● | ● | - | |

| Independent front/rear touch bar emergency stop | ● | ● | - | - | ● | |

| Remote control | ● | ● | ● | ● | ● | |

Application

Ackermann steering geometry is widely used in a variety of scenarios due to its efficient steering efficiency and mechanical reliability. It is particularly suitable for environments that require long-distance straight-line driving, low-energy steering, or fixed path planning.

Logistics and Warehousing Robots

AGV (Automated Guided Vehicle):

Warehouse transportation: Long-distance straight-line driving + fixed path navigation, with the Ackermann chassis offering significant energy efficiency and long battery life.

Port unmanned transport vehicles: In heavy-load scenarios, the reliability of mechanical structures is superior to omnidirectional wheel solutions.

Unmanned delivery vehicles

Urban road cruising: Combining electronic power steering (EPS) and path planning algorithms to achieve efficient obstacle avoidance and turning.

Outdoor Operation Robot Chassis

Agricultural Robot Chassis

Farmland spraying/sowing: High demand for fixed trajectory operations, Ackermann chassis suitable for uneven terrain (suspension adjustment required).

Orchard/Forest Inspection Vehicles

Long-Distance Patrol: Offers superior battery endurance and mechanical durability compared to differential steering systems, making it ideal for extended outdoor missions in orchards or forested areas.

Campus/Industrial Park Inspection Robots

Fixed route patrol: Such as factory and warehouse security robots, which have obvious advantages in terms of low energy consumption and long operating time.

Product Classification

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +