Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +

Henan Xspirebot

Xspirebot specializes in the design, production, and servicing of robot platform solutions.

Quality Control

A comprehensive quality control system that manages everything from raw materials to finished products.

Service & After sales

24-hour after-sales service. Please do not hesitate to contact us if you have any questions.

Download

XspireBot provide downloads of product catalogs, product solutions, and user manuals.

Key Member

Ten years of mass production experience and 32 patents in motion control.

Agricultural Industry

Agricultural robot chassis assists you in field operations such as sowing, spraying, and harvesting.

Manufacturing Industry

Industrial robot chassis assist you with tasks such as material handling, assembly, and quality inspection.

Transportation Industry

Autonomous transport robots that can deliver goods around the clock in urban and industrial environments.

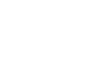

Warehousing Industry

Unmanned transport robots enable full autonomy in cargo stacking & transfer within IoT logistics.

Inspection Industry

Autonomous 24/7 patrols at power facilities, industrial sites, data centers, and other locations.

Firefighting Industry

Autonomous fire detection & suppression in high-risk environments: high-rises, chemical plants, and data centers.

Robot Chassis

Xspirebot offers chassis for indoor and outdoor mobile robots suitable for different terrains.

Motors

Drive motor designed for mobile robot chassis, applied to mobile robot platform & agricultural robot chassis.

Controller/Drive

The controller can control the robot chassis's movement, positioning, obstacle avoidance, path planning, and other motion functions.

Sensor

Xspirebot offers advanced sensors for autonomous robot platforms: cameras, ultrasonic radar, LiDAR, IMU, & IINS.

Electric Motor Axle

Xspirebot adapts electric transaxle load, power output, & layout to meet customer needs.

Wired Components

Line control braking & steering enhance vehicle control efficiency & precision via electronic signals.

Energy

Solar panels & batteries offer flexible solutions, letting you choose components to suit your needs.

Company News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Exhibition News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Industry News

Xspirebot is committed to helping our customers reduce development costs, shorten the R&D cycle, and accelerate the mass production process through platformized and modularized architectural design and standardized production processes.

Motors

Xspirebot provides global developers, manufacturers, and research institutions with full-stack solutions for three core drive technologies: hub motors, servo motors, and servo actuators, helping your robot chassis achieve a triple leap in power, precision, and efficiency!

Let every robot chassis become a fulcrum for changing the world!

In mobile robot chassis, the chassis drive system directly affects the chassis's motion performance, application scenario adaptability, and development cycle. As the most core mechanical actuator of mobile robots, the drive system needs to simultaneously meet multiple requirements such as power transmission efficiency, positioning accuracy, and environmental adaptability.

Our company's wheeled robot chassis primarily employs the following three drive systems: hub motors, servo motors, and steering motors. Hub motors are suitable for robots requiring all-wheel drive or independent wheel control, such as off-road or omnidirectional mobile platforms, and are ideal for designs with limited space. Servo motors are suitable for applications requiring high-precision control, such as medical robots or precise positioning tasks. Steering motors are suitable for robots requiring traditional steering mechanisms, such as path following or obstacle avoidance, but are not suitable for designs primarily relying on differential steering.

Hub Motors

Hub motors are a highly integrated drive solution that is particularly well suited for mobile robotics applications. By integrating the motor directly into the wheel, hub motors offer the advantages of high torque, fast response, and a highly integrated design, making them ideal for a wide range of applications such as AGVs, service robots, off-road robots, or omnidirectional mobile platforms.

High integration and space efficiency: By integrating the motor directly into the wheel, the number of mechanical components is reduced, simplifying the design and assembly of the robot chassis, making it particularly suitable for robot platforms with limited space.

High torque output: It can provide high torque at low speeds, making it suitable for mobile robot chassis requiring rapid acceleration or heavy-load carrying capabilities.

High responsiveness: Direct drive reduces mechanical transmission losses, enhancing the response speed and control precision of the robot chassis.

All-wheel drive capability: Hub motors enable independent drive for each wheel, making them suitable for robots requiring omnidirectional mobility or off-road capabilities.

Servo Motor

A servo motor is a precision control motor used to achieve precise positioning and speed control for rotational or linear motion. Its core lies in its closed-loop control system, which uses feedback mechanisms (such as encoders or Hall sensors) to monitor and adjust the motor's position and speed in real time. This makes it ideal for tasks requiring precise navigation, such as warehouse robots or service robots.

High precision: Servo motors can provide micron-level positioning accuracy, making them suitable for tasks requiring precise navigation or operation, such as industrial automation or medical robots.

Quick response: Their closed-loop control system ensures rapid acceleration and deceleration response, making them suitable for dynamic environments.

Energy efficiency: Servo motors only consume power when moving, making them suitable for battery-powered mobile robots.

Compact design: Their miniaturization and high torque characteristics make them suitable for robot platforms with limited space.

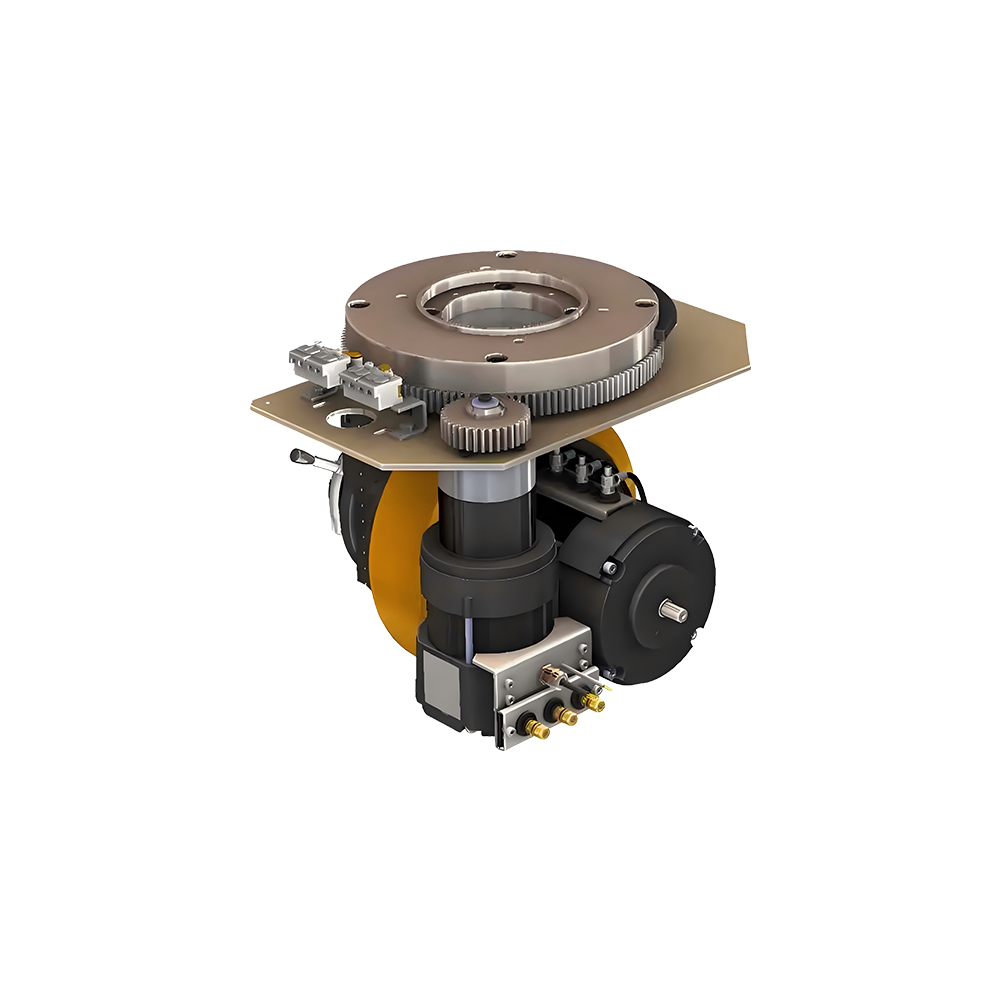

Electric Steering Motor

An electric steering motor is a motor specifically designed to control the steering of mobile robots. It typically achieves directional control by precisely adjusting the angle of the wheels, making it suitable for robots that require complex path planning. It is commonly found in robot chassis that use traditional steering systems, such as Ackermann steering.

High-precision control: Through closed-loop control and feedback sensors (such as encoders or Hall sensors), the servo motor can achieve micron-level steering precision, making it suitable for tasks that require precise navigation.

High adaptability: Compatible with various steering mechanisms, such as Ackermann steering or omnidirectional movement, to meet diverse application requirements.

Compact design: Highly integrated, easy to install and maintain, suitable for robot platforms with limited space.

Reliability: Servo motors are crucial in service-oriented robot applications, especially in scenarios requiring high uptime.

Product Classification

Accelerating the Robot Dream

Empowering robot innovation, providing full-cycle development services, reducing costs, and accelerating the commercialization process.

Contact Us +